Tetrahedron - cutting cost in offshore wind turbine installation

Publieke samenvatting / Public summary

Due to the growth of offshore wind turbines from average 7.5MW in 2018 towards an expected 10-20MW in 2025 the installation requirements change significantly.

Foundations become so heavy that floating crane vessels become cost-efficient. The wind turbine generator (topside) becomes that high and heavy, that existing jack-up-vessels can’t lift high enough anymore. It is hardly possible to upgrade an existing jack-up-vessel with a conventional luffing boom crane because the jack-up-vessel cannot handle the overturning moment of the larger crane and is not suitable to accommodate a larger crane boom length. Based on conventional technology, the only solution is to simply build a new larger jack-up-vessel (in Asia). However, this will be cost-inefficient, because building a new large jack-up-vessel is exposed to a high CAPEX-repayment. With a new type of crane, the Tetrahedron, capacity at height could be reached cost-efficiently by using compact new built vessels in the future, and today far more cost-efficiently using Tetrahedron upgraded existing jack-up vessels.

Objective

Tetrahedron B.V. proved with previous studies, that the Tetrahedron crane design principle boosts the lifting height with approximate 50%, without compromising the crane performance. With this, we can prove a significant cost reduction in the installation of the next generation 10-20MW wind turbines. These positive effects are a consequence of principally different motion and force flow. However, because of a new motion and different force flow, there is no experience in operating a Tetrahedron crane, neither a track record of (safe) working. For the Tetrahedron crane’s unique motion and structural characteristics, additional research is required. The target of this R&D project is to search for practical design constraints and operational procedures for a Tetrahedron crane and prove these operations and the crane design itself are safe.

Short description

The consortium (in this phase led by the potential end-user Van Oord) sets the operational requirements for the installation of 10-20MW wind turbine generators (topside). The crane-design & engineering company Tetrahedron B.V. and Van Oord dimension a Tetrahedron crane suitable for a refit upgrade onto Van Oord‘s Aeolus jack-up-vessel. Led by the TU-Delft this consortium and consultant DNV-GL will perform a risk assessment and generate an extensive list of potential failure modes. When the likelihood and consequences of the failure modes are known, measures can be taken to either avoid the failure mode of happening at all or controlling the consequence. The mitigating measures taken might have a significant influence on the original Tetrahedron crane design. The technical research to the failure modes and the measures to avoid it from happening will be presented by technical drawings including the underlying calculations. Since the ‘measures’ to avoid failure modes from happening might influence the operation duration or the crane cost, the business case will be reviewed as part of the research.

Results

After completing this project, the safety of the Tetrahedron crane principle in a realistic 10-20MW offshore wind turbine generation installation project is quantified. This research eliminates operational and technical principle questions compared to the conventional luffing boom crane. That means that a qualitative cost-effectiveness analysis can be made. The additional result will then be cost presentation of a single wind turbine generator installation with the Tetrahedron crane compared to the cost of installation with the conventional luffing boom crane.

News Item

12 January 2021

Tetrahedron wins Windpower Monthly’s award for novel offshore wind crane

Tetrahedron’s Offshore Wind cranes today won Windpower Monthly’s innovation of the year, selected for their novel cranes that can be used to both upgrade existing and be installed on new Wind Turbine Installation Vessels to meet the installation challenges of the next generation of 12 – 20 MW offshore wind turbines.

A key criterion for the selection of Tetrahedron for the award was efficient force flow through the tetrahedron crane structure, which translates to an ultra-high lifting solution offering an extra ~50 meters of lifting height over alternative solutions on the same vessel while lifting performance is preserved. As highlighted by Windpower Monthly, “The innovation could hugely contribute to continued deployment of many early installation vessels, which for a sound business case should remain in active service for 20 – 25 years”.

While there is significant interest for new builds, the crane can also be used to upgrade existing wind turbine installation vessels, allowing non-competitive vessels to be upgraded to install up to 12-20MW turbines with an investment 1/5th the cost of a new unit. For units as small as the Seajacks Zaratan, 12-20MW capable cranes can be installed with minimal modification to the hull, as the novel design results in lower load moments on the hull even compared to the existing, smaller cranes currently installed.

Jack-up vessel upgrades in practice

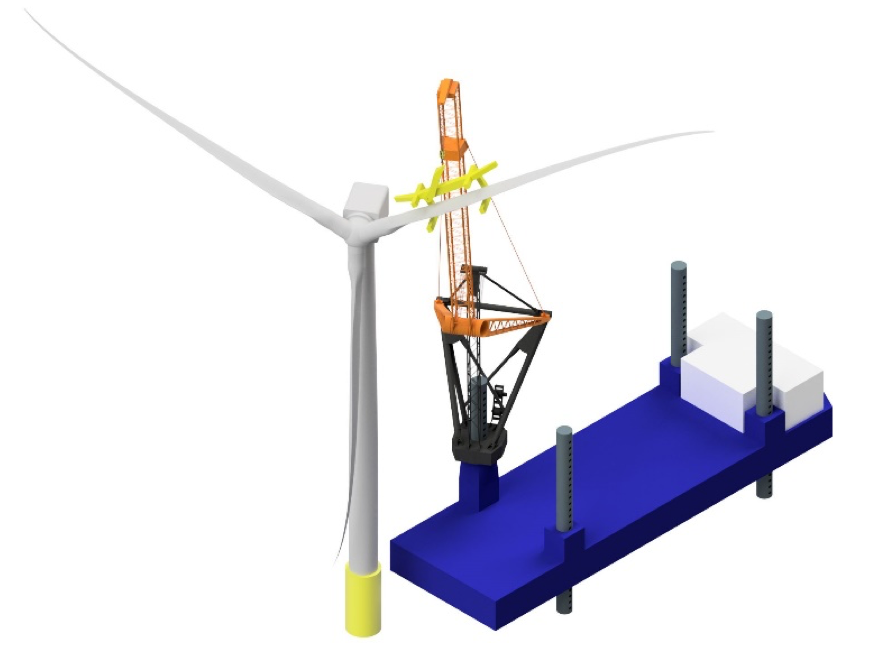

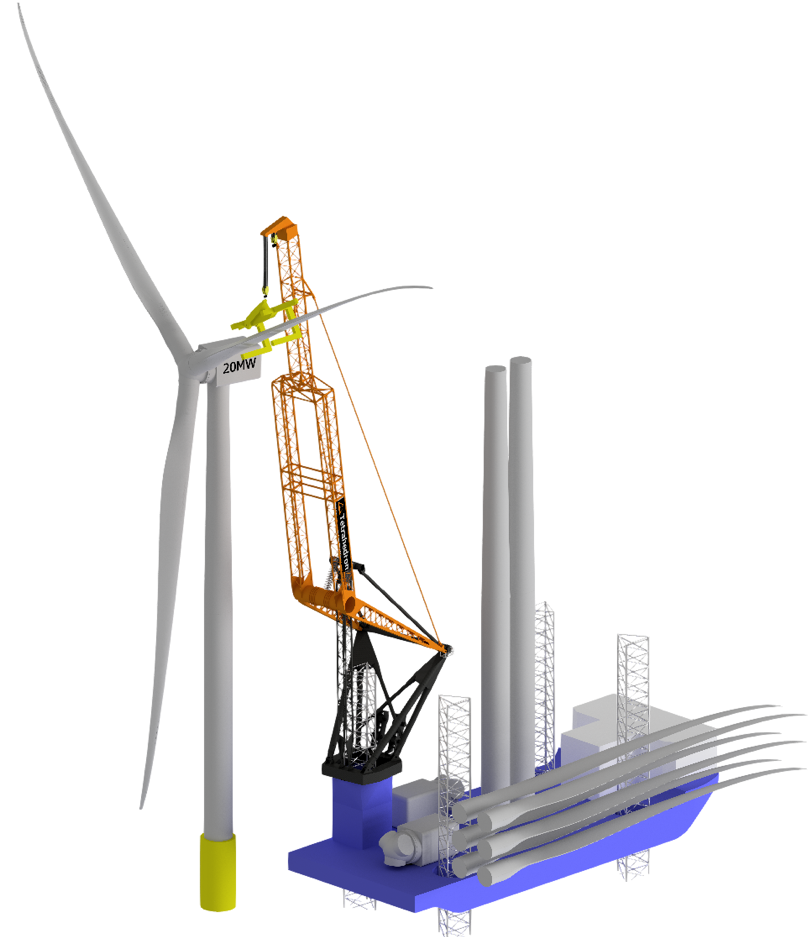

Designs have been developed to fit on tubular-legged jack-up vessels such as the Ziton Wind Enterprise and ZPMC Torben (see figure 1). Tetrahedron has also developed a design that accomodates a split jib (see figure 2), perfect for units such as Van Oord’s Adventure and Aeolus, Jan de Nul’s Taillevent and Vole Au Vent, DEME’s Sea Installer and Sea Challenger, and Fred Olsen’s Bold Tern. Lastly, Tetrahedron can also accommodate units with lattice legs that require large a opening in the slewplatform (see figure 3), allowing vessels like the DEME Apollo and Innovation, Teras Sunrise, Seajacks Scylla and Fred Olsen’s Blue Tern to be upgraded economically to meet the future challenges of the Offshore Wind industry.

The upgrades represent an attractive business case for existing operators and new entrants, especially when feeder solutions are considered, which require large lifting heights without a large focus on deck space, and with minimal investment allow existing non-competitive installation vessels to re-enter the construction market and compete with expensive new builds.

About Tetrahedron company

Tetrahedron is a young Offshore Wind Engineering company in Rotterdam, the Netherlands. The design of the crane is completed and verified by DNV GL and is prepared for delivery and upgrade executed in Rotterdam. The company is led by Wilco Stavenuiter, a 12 year veteran of the Offshore Lifting industry, and supported by a strong engineering team led by Alexander Ronse.

Figure 1: Tetrahedron configured around a tubular leg of a compact jackup (such as existing jackups: Seajacks Scylla, Ziton Wind Enterprise, ZPMC Torben, and so on).

Figure 2: Tetrahedron crane configured around a tubular leg with a jib-split to stow the jib around the front leg (such as existing jackups: Van Oord’s Adventure and Aeolus, Jan De Nul’s Taillevent and Vole au vent, DEME’s Sea Installer and Sea Challenger, and Fred Olsen’s Bold Tern, and so on)

Figure 3: Tetrahedron crane configured around a lattice leg and with a jib split to store the crane around the front leg – here installing a 20 MW turbine (suitable to upgrade jackups such as the DEME Innovation, Teras Sunrise, Seajacks Scylla and Fred Olsen’s Blue Tern and so on).

---------------------------------------------------------------------------------------------------------------------------------

For furher information about Windpower Monthly their award:

https://www.windpowermonthly.com/article/1704144/turbines-year-2020-innovations (public)

https://www.windpowermonthly.com/article/1704123/read-january-edition-windpower-monthly-page-by-page-online-now (in the paid journal)

For further information about the Tetrahedron crane please look at:

www.tetrahedron.tech and follow us at https://www.linkedin.com/company/tetrahedron-cranes/ for technology developments updates.

For further information about Tetrahedron company or other, please contact:

info@tetrahedron.tech / or call +31 102613038 (European time zone)